John Deere parts and service support provide uptime for a timely harvest

Sales and service delivered

Sales and service delivered

Sales, parts, and service support from a local John Deere dealer offers overnight parts delivery and a well-trained support staff.

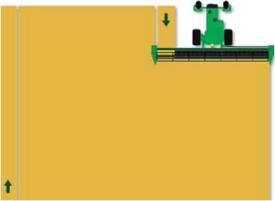

Hydraulic deck shift gives larger windrows for more efficient harvesting

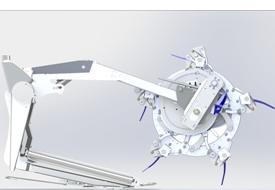

Transport easily with integrated transport system

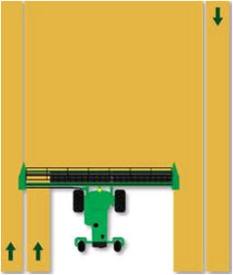

400D integral slow-speed transport system (W155 shown)

400D integral slow-speed transport system (W155 shown)

Slow-speed transport system:

- 400D Drapers are towable only with W155 and W170 Self-Propelled Windrowers

- Transport is recommended behind a tractor with seven-pin electrical lighting outlet

- 430D, 435D and 440D Drapers only

- Convert draper from field to transport in minutes with one person and without tools

- Dual front dolly wheel tires and two, gauge wheel tires carry weight of transport

It is a simple four-step process to switch from field to transport:

- Move right gauge wheels from field to transport

- Move left gauge wheels from field to transport

- Attach the tongue.

- Detach from the windrower.

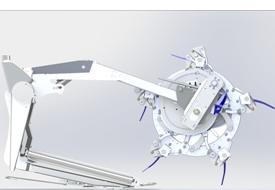

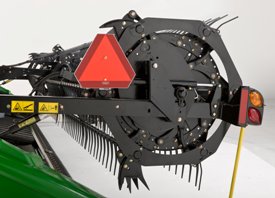

Optional reverser clears plugs effortlessly for higher productivity during tough harvest conditions

Platform reverser controls on W155

Platform reverser controls on W155

Platform reverser controls are available for the W155 Self-Propelled Windrower only:

- Easily activated from operator's station to clear platform of plugs

- Reverser slowly reverses the knife drive and optional hay conditioner, if equipped, to clear plugs

- Highly recommended when using optional hay conditioner with 400D Platforms

- Operators can run machines closer to their maximum capacity and it will take less time to unplug

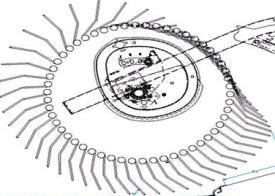

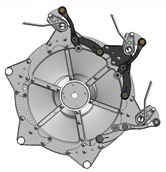

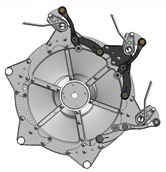

Reverser valve block

Reverser valve block

The reverser consists of a valve block and valves, shown in the image above. It is the gold-colored valve block on the right side. It is shown plumbed for a 100A Auger Platform.

Cutterbar and frame profile gives uninterrupted crop flow

C-shaped cutterbar profile

C-shaped cutterbar profile

The C-shaped cutterbar profile provides:

- Smooth crop flow

- Superior draper-to-cutterbar seal

- Reduced amount of material under belts

- Minimized crop loss in shatter-prone crops

Gauge wheels provide ground following for uniform cut

Dual gauge wheel option

Dual gauge wheel option

400D Series Draper Platforms offer optional dual gauge wheels with spring suspension:

- 1-cm (15-in.)

- Excellent ground following and flotation in all conditions

- Fine adjust the float on the go from the cab for high-speed harvesting and stable flotation

- Available as part of the integrated slow-speed transport system option

Excellent visibility to cutterbar and belt

Strong, positive-feeding reel handles all crop conditions

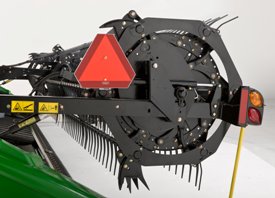

435D split-span reel with plastic fingers

435D split-span reel with plastic fingers

Cam reel tooth action

Cam reel tooth action

Reel in full forward position

Reel in full forward position

The cam reel design of the 400D Series Draper Platform features:

- 165-cm (65-in) diameter

- Heavy-duty plastic or steel fingers

- Tooth position control

- Smoother and quieter operation at higher reel speeds

- Less wear on reel drive components

- Less shattering of the crop

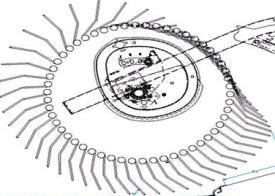

Hourglass-shaped reel

Hourglass-shaped reel

Reel end fingers

Reel end fingers

The hourglass-shaped reel has:

- End positioned closer to the cutterbar to provide smooth feeding

- Adjustable bolt position to change distance of reel to cutterbar

Adjustable cam positions

Adjustable cam positions

The cam position and reel position are adjustable, enabling the machine settings to be matched with the crop conditions for a trouble-free harvest. The finger release position is easily adjustable to one of four cam positions.

The reel is hydraulically positioned up, down, and fore-aft to allow perfect positioning for gentle yet positive feeding action.

Plastic fingers:

- Standard from the factory on all 400D Series Platforms

- Recommended for all crop conditions

- Lighter weight and easy to replace

Steel fingers:

- Only available through Parts

- Recommended for heavy forage crop

- Longer life

Optional end fingers improve feeding aggressiveness in difficult feeding and cutting conditions with down and tangled crop.

Plastic tine split reel with end feed fingers

Plastic tine split reel with end feed fingers

Single span reel:

- Available on 415D, 420D, 425D, 430D and 435D Drapers

- Less weight

- Better center visibility

- Good option for canola and small grains harvesting

Double span reel:

- Available on 430D, 435D and 440D Drapers

- Better feeding in heavy, wet, or down crop

- Better control of the reel height for more consistent feeding

Five-bat reel

Five-bat reel

Six-bat reel

Six-bat reel

Nine-bat reel

Nine-bat reel

The reel is available in five-six- or nine-bat configurations:

- Six- to nine-bat conversion is available with field installation

- Recommended for heavy conditions such as silage or grass seed crops

|

Cutterbar

|

| Type |

Dual knife base

Single knife base optional |

| Cut width (length) |

7.6 m

25 ft |

| Knife drive |

Hydraulic motor to belt to enclosed heavy-duty wobble box |

| Knife speed |

Dual: 700-850 cycles/min

1,400-1,700 spm

Single: 600-700 cycles/min

1,200-1,500 spm |

| Cutterbar tilt |

Standard hydraulic

Optional mechanical (7.5 to 17.0 degree lift) |

|

Reel

|

| Reel type |

Pick up cam 4 position adjustable release |

| Number of bats |

6 bats standard

9 bats optional, single span, capped ends |

| Fingers |

Heavy-duty plastic |

| Diameter |

1,650 mm

65 in. |

| Height control |

Hydraulic |

|

Draper and decks

|

| Speed control |

Hydraulic from cab |

|

Reel

|

| Reel lift |

Hydraulic |

| Reel fore and aft |

Hydraulic |

| Operating speeds |

0-85 rpm |

|

Draper belts

|

| Width |

Wide rubber skim-coated 710-ml (24-oz) drapers: 1,067 mm

41.6 in. |

|

Draper and decks

|

| Operating speed |

0-225 m/min

0-742 fpm |

|

Header height sensing

|

| Header height sensing on the ground |

Float springs on traction unit |

| Header height sensing off the ground |

Return to cut height standard

Gauge wheels optional |

|

Dimensions

|

| Platform length |

8 m

26.3 ft |

| Overall operating depth |

With crop dividers 2.6 m

8.7 ft |

| Transport width, field position |

8 m

26.3 ft |

| Transport width on wheel, less dividers |

2.5 m

8.1 ft |

|

Weight

|

| Approximate weight (pickup reel) |

1,589-1,861 kg

3,500-4,100 lb |

|

Center opening / crop delivery

|

| Center opening width between belts |

1,720-1,950 mm

67.1-76.7 in. |

| Deck shift / double windrow capability (manual / hydraulic / not available) |

Manual standard

Hydraulic optional |

|

Key Specs

|

| Cutterbar - Type |

Dual knife base

Single knife base optional |

|

Draper and decks

|

| Belt width |

Wide rubber skim-coated 710-ml (24-oz) drapers: 1,067 mm

41.6 in. |

|

Weight

|

| Approximate weight (base platform with reel) |

1,589-1,861 kg

3,500-4,100 lb |

Accessories and Attachments

Spare Knife, One-Piece with Knife Head Coarse Cut - 25 Ft. - BE32422

Non Clog Guard Kit - 425D - BE32391

Hydraulic Drive Kit - Double Draper & Top Crop Converging Auger - BE32419

Vertical Knife Mounts - LH - BE32401

Vertical Knife Mounts - RH - BE32402

6 Bat to 9 Bat Reel Conversion Kit - 425D - BE32397

End Swath Deflector Rods (For LH End) - BE32379

End Swath Deflector Rods (For RH End) - BE32380

Top Crop Conveying Auger - 25 Ft. - BE32414

Reverser - W150 or W155 Only - BE32361

The W110 and W150 feature multiple attachments to improve the machine productivity and operator convenience.

Wiring Harness and Hitch Pin Kit - BE32429

The W110 and W150 feature multiple attachments to improve the machine productivity and operator convenience.

Windrow Merger Attachment for W150 - BE32428

The W110 and W150 feature multiple attachments to improve the machine productivity and operator convenience.

Weight Box (With Weight) For Transport Less Platform (U.S. and Canada Only) - BE32366

The W110 and W150 feature multiple attachments to improve the machine productivity and operator convenience.

Weight Box (Less Weight) For Transport Less Platform (Outside of U.S. and Canada Only) - BE32367

The W110 and W150 feature multiple attachments to improve the machine productivity and operator convenience.

Inboard Gauge Shoes with Poly (Set of 2) - BE32400

Cutterbar Full Width Poly Skid Shoes and Hardware Kit - 425D - BE32407

Swath Forming Rods (Center Delivery) - BE32381

Steel End Finger Kit for Reel - BE32404

Hay Conditioner with Center Feed Section - BE32386

Draper Extension Kit - BE32387

Hose Kit, 400D Draper Platform Case Drain Kit - BE32510

Auxiliary Vertical Knife Plumbing Kit - BE32403