Wide or narrow axle available to fit a variety of cropping row widths

Wide axle, 234 cm to 307 cm (92 in. to 121 in.)

Wide axle, 234 cm to 307 cm (92 in. to 121 in.) Narrow axle, 183 cm to 224 cm (72 in. to 88 in.)

Narrow axle, 183 cm to 224 cm (72 in. to 88 in.)Two axle widths are available to best fit a variety of cropping row widths.

The narrow width axle has a tread width from 183 cm to 224 cm (72 in. to 88 in.) and a clearance of 112 cm (44 in.). The wide axle has a tread width from 234 cm to 307 cm (92 in. to 121 in.) and a clearance of 127 cm (50 in.). Axle range for wide machines varies slightly depending on the option (hydraulic vs. manual tread adjust) that is being used.

Â

NOTE: In order to achieve 229-cm (90-in.) tread spacing, IF320/80R42 tires must be used with AN401678 rims. Please see your local John Deere Dealer for more information.

Â

With these tread spacings, the R4023 Sprayer holds an impressive 46-54 weight split when unfolded, fully loaded. This weight split helps to reduce compaction through the field and keeps the power to the ground.

The wide axle is ideal for the Midwest grain farmer. With the wide axle option, the operator can straddle three rows at 76.2-cm (30-in.), 81.3-cm (32-in.), 86.4-cm (34-in.), 91.4-cm (36-in.), 96.5-cm (38-in.), or 101.6-cm (40-in.) spacing or four rows at 76.2-cm (30-in.) spacing.

The narrow axle is ideal for the cotton or specialty crop farmer. With the narrow axle option, the operator can straddle two rows at 91.4-cm (36-in.), 96.5-cm (38-in.), or 101.6-cm (40-in.) row spacing.

Air bag/shock suspended axle provides a comfortable ride even in rough conditions

Cast mount for connecting rods

Cast mount for connecting rods

The suspension design on the R4023 Sprayer uses a four-bar link system along with an air bag and shock combination to provide a comfortable ride.

Two large air springs sit atop each axle, similar to those used on over-the-road trucks and other John Deere sprayers. These air springs are dampened with oil-filled shocks to smooth the ride.

Connecting rods link the axle to the large cast mount that is bolted to the C-channel frame with a Huck® bolt. The axle-connecting rods are parallel for vertical motion and cross linked for lateral stability.

Air bag/shock suspension

Air bag/shock suspension

The R4023 Sprayer's standard suspension provides for 152 mm (6 in.) of travel at the air bag. The air springs are underneath the frame; therefore, visibility of the rows passing underneath is free of suspension components.

The air springs are adjusted by adding or removing air through a standard air-stem valve on top of each spring or, if the sprayer is equipped with auto air-spring leveling, the air springs will inflate to the optimum level for the best-possible ride.

Auto air-spring leveling system adjusts for optimal field performance

The auto air-spring leveling system is standard equipment. This feature maintains ride height, ensuring 102 mm (4 in.) of travel up and down at all times for 203 mm (8 in.) of total travel. The operator does not have to individually fill each bag or deflate each bag for transport, saving as much as 10 minutes. A switch located near the solution loading system deflates all four bags at one time. Once the machine is running, the on-board air compressor automatically inflates the bags to the optimal set ride height.

Huck is a trademark of Alcoa Incorporated.

Huck®-bolted C-channel frame lays the foundation for a smooth ride

Huck bolt outside frame

Huck bolt outside frame Huck bolt inside frame

Huck bolt inside frameThe R4023 Sprayer's great ride begins with the frame. The frame construction allows the R4023 Sprayer to absorb rough field conditions that the operator may encounter.Â

The frame consist of two strong parallel C-channels that are connected by suspension castings and reinforcement cross members. The cross members are connected to the frame using Huck bolts. Huck bolts combine the advantages of a high-strength bolt and rivet.

These fasteners provide greater vibration resistance and a joint that will never loosen compared to standard bolts.Â

This style of frame and fastener is commonly used on over-the-road trucks and trailers.

Huck is a trademark of Alcoa Incorporated.

Soft Shock option for rough or uneven terrain applications

The R4023 now offers two factory installed shock solutions to accommodate various field conditions. For optimal comfort in rough or uneven terrain conditions such as no-till or stripped fields, a Soft Shock option is now available.

The Soft Shock will take the place of the adjustable shock dampener used on the 4630 and will be offered as a factory-installed option. This fixed shock provides 50 percent less dampening force which allows for a smooth ride up to 32.2 km/h (20-mph) spray speed in those uneven field conditions. The Soft Shock may also provide a more responsive feel for operators in turns or when starting/stopping quickly.

NOTE: The standard shock option is unchanged from previous models and is recommended for general use.

Redesigned CommandARM™ console and multifunction handle improves operator experience

R4023 operator station

R4023 operator stationWhen operators first enter the model year 2018 R4023 cab, they will notice that there have been significant changes made. Key sprayer controls are more easily accessible to the operator on the redesigned CommandARM and the multifunction handle has a more ergonomic fit and feel.

The multifunction handle has six reconfigurable buttons, a scroll to select speed range, and allows operators to better manage their headlands with the Headland Management System (HMS™) button.

To finish out the upgrades, the GreenStar™ display has been upgraded to a faster, more user-friendly 4600 CommandCenter™ display, which allows operators to efficiently capture, manage, and transfer data.

Optimal weight distribution means operator can get into field earlier

Having the optimal weight distribution results in a lighter footprint leaving less compaction and less damage to the field, allowing the operator to get into the field earlier.

The R4023 Sprayer was built with the optimal weight distribution.

R4023 Self-Propelled Sprayer | Front weight

(kg, lb) | Rear

weight

(kg, lb) | Machine weight

(kg, lb) | Weight

distribution (percent) |

| Total | Total | Total | Front | Rear |

| Base machine empty with booms folded, 24.3-m (80-ft) boom | 5,048 (11,105) | 3,227 (7,100) | 8,275(18,205) | 61 | 39 |

| Base machine empty with booms unfolded, 24.3-m (80-ft) boom | 4,220 (9,285) | 4,055 (8,920) | 8,275 (18,205) | 51 | 49 |

| Base machine full water with booms folded, 24.3-m (80-ft) boom | 5,912 (13,006) | 5,036 (11,079) | 10,948 (24,086) | 54 | 46 |

| Base machine full water with booms unfolded, 24.3-m (80-ft) boom | 5,146 (11,320) | 5,802 (12,765) | 10,948 (24,086) | 47 | 53 |

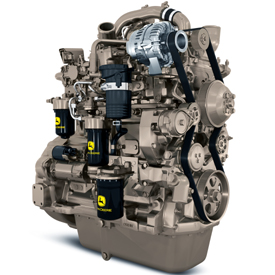

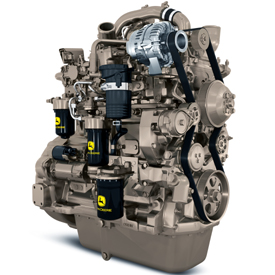

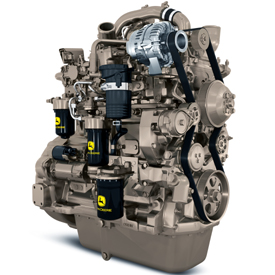

Provides 129-kW (173-hp) turbocharged PowerTech™ PSS 4.5L Tier 4 diesel engine

4.5L John Deere PowerTech PSS diesel engine

4.5L John Deere PowerTech PSS diesel engineThe R4023 Sprayer provides 129 kW (173 hp) with a 5 percent power bulge to 136 kW (182 hp) and 6071 kg/cu m (538 lb-ft) of peak torque to get through tough field conditions.

John Deere PowerTech PSS (two-valve) 4.5L engine features include:

- Four-cylinder, eight-valve head (two valves per cylinder)

- Cooled exhaust gas recirculation (EGR)

- Exhaust filters

- Selective catalytic reduction (SCR)

- Air-to-air charge air cooler (CAC), aftercooled

- High-pressure common rail (HPCR) fuel injection system

- Series turbocharger

In addition to reducing emissions and lowering engine idle noise, its compact size allows it to fit neatly under the hood for great visibility of the rows passing underneath the operator.

An increase in fuel tank size makes it possible to spray for up to 16 hours without refueling. By equipping the R4023 Sprayer with a 310-L (82-gal.) fuel tank, the operator will have plenty of fuel to spray for a full day.

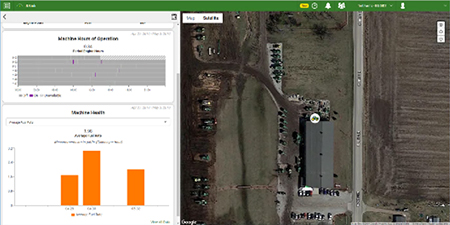

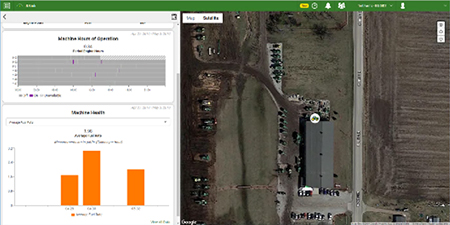

Enhance management skills with JDLink™ Connect system

Machines compatible with JDLink Connect

Machines compatible with JDLink ConnectA. 9030 and 9R/RT Tractors

B. 8030 and 8R/RT Tractors

C. 7030 and 7R Tractors

D. 6030 and 6R Tractors

E. W200 Series Windrowers

F. 7760, CP690, and CS690 Cotton Pickers and Strippers

G. S, T, W Series Combines

H. 7050, 7080, and 8000 Series Self-Propelled Forage Harvesters

I. R4030, R4038, 4630, 4730, 4830, 4940 Sprayers

NOTE: Not all products or models are available in all regions. Refer to your local John Deere Dealer for product availability.

JDLink Connect is the premium telematics product offered by John Deere. The above key and pictures shows the list of machines compatible with JDLink Connect. JDLink Connect uses machine power and is designed to:

Evaluate machine performance and efficiency to make informed, timely decisions

Coordinate labor and machine logistics

Stay connected using remote management tools

View location history

Use remote diagnostics

Work in harsh agricultural conditions

Support maintenance schedule and alerts

Get the expert's opinion faster to keep an operation working

NOTE: JDLink Connect features are model dependent. Confirm with a John Deere dealer what specific features are available.

- View tractor selective control valve (SCV) and hitch settings remotely thanks to JDLink Connect

- Boost productivity by monitoring machine settings and detailed machine states on combines

- Increase productivity with awareness of detailed information for SPFHs enabled by JDLink Connect

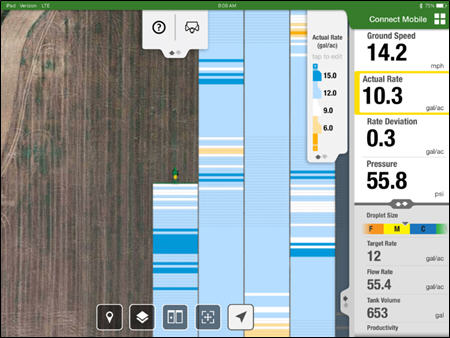

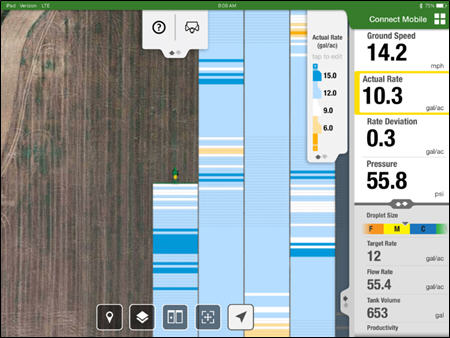

Monitor sprayer performance in the cab

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performanceConnect Mobile overview

John Deere Connect Mobile is a solution that utilizes an Apple® iPad® tablet in the cab that provides the operator a better understanding of the sprayer’s performance. Connect Mobile documents and displays several sprayer performance attributes, helping the operator monitor and more easily detect problems that can occur while spraying. Connect Mobile also has a common user interface that makes it easy to use between different pieces of John Deere equipment. Once the job is done, the iPad with the spraying data can be utilized to perform basic crop scouting activities in the field.

Spraying attributes

Monitor key performance indicators in map layers and dashboard tiles such as:

- Actual rate

- Rate deviation

- Pressure

- Ground speed

- Droplet size

- Target rate

- Flow rate

- Tank volume

- Productivity

- Fuel rate

In base equipment

Connect Mobile hardware is factory installed on all model year 2017 and newer R4030, R4038, and R4045 Sprayers, making it easy to get started with Connect Mobile.

Learn more about Connect Mobile in the Field and Crop Solutions section within the Precision Ag Technology product line and how it can improve the quality of a spraying job.

iPad and Apple are trademarks of Apple Inc.

Boom structure built with high-strength square tube

Interchangeable inner booms

Interchangeable inner booms 3-D boom structure

3-D boom structureThe R4023 Sprayer's booms are built with high-strength square tube.

The boom incorporates a strong 3-D design. This design gives the boom more strength to resist fore-aft loading generated by starts, stops, and turns, as well as twisting loads caused by folding and unfolding operations.

The boom plumbing and nozzles are set between and up inside the two bottom square tubes of the boom structure. This protects the nozzle bodies from hitting objects that could damage the sprayer or affect the spray pattern.

The R4023 boom comes in an 18.3-m/24.4-m (60-ft/80-ft) or 18.29-m/27.44-m (60-ft/90-ft) configuration. Simply fold in the outer wing and go from spraying at 24.4 m/27.44 m to 18.3 m (80 ft/90 ft to 60 ft). When the outer wing is folded over top, it is supported by cradles to ensure it will remain in place and secure while spraying in the 18.3-m (60-ft) configuration in rough fields.

Increased boom sections provide the operator more precise application:

- 24.4-m (80-ft) boom-5 sections

- 27-m (90-ft) boom-7 sections

The breakaway ends of the boom offer the operator protection against damaging the boom if the boom unexpectedly hits an obstacle. The breakaway section of the boom uses a design that holds the breakaway from breaking backward while operating normally in the field, but when something is contacted, it will move rearward and out of the way to prevent major damage.

Each breakaway section resets using a spring, and then resets back to the spray position.

When the booms are folded in, the transport cradles on the machine support a large portion of the boom that, in turn, spreads out the stress.

While in transport position, the booms are cradled so that visibility is maximized to either side of the sprayer. By folding the booms flat, visibility is increased and the overall height of the machine is not affected.

Get the most out of every drop with ExactApply™ system

Increase productivity up to 20 acres per hour* through wider spray speeds and rate ranges. Better manage drift and improve spray quality and precise application.

*NOTE: Assumes a 3.2-km/h (2-mph) average operating speed increase.

Wider speed range while maintaining target rate and pressure

Consistent droplet size is critical to drift management and precise application. The ExactApply system produces a consistent droplet size through:

- 15/30-hz pulse width modulation that maintains spray pressure throughout a wider speed and rate range

- Automatic nozzle switching between two nozzles that maintains the desired spray pressure range while conventional spraying

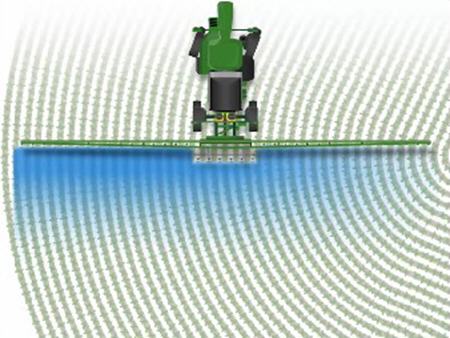

Turn compensation

Control gallons per acre throughout turns

Control gallons per acre throughout turnsConventional spraying technology applies the same rate throughout the width of the boom while turning, causing under application on the outside of the boom and over application on the inside of the boom.

ExactApply varies the rate across the boom, ensuring the desired application rate. The rate decreases on the inside of the turn to not subject crop to chemical burn, while the rate on the outside of boom increases, ensuring the crop receives the desired application rate.

Individual nozzle control

Traditional nozzle control functions in 11 sections, meaning section widths vary from 2.4 to 3.35 m (8 to 11 ft), depending upon boom width.

Avoid spraying waterways while ensuring coverage

Avoid spraying waterways while ensuring coverageIndividual nozzle control minimizes overlap by controlling product application through individual nozzles. This reduces chemical cost and ensures the product is placed where it is needed most.

ExactApply™ nozzle control delivers precise application with up to 20 acres per hour of added productivity

Turn compensation mode

Turn compensation mode

Individual nozzle control mode

Individual nozzle control mode

John Deere’s intelligent nozzle control system ExactApply helps producers better manage drift and deliver a precise application. By maintaining target rate and pressure over a wider speed range, ExactApply can improve productivity up to 20 acres per hour*.

*NOTE: Assumes a 3.2-km/h (2-mph) average operating speed increase.

ExactApply is offered as a factory-installed option as well as a performance upgrade kit that can be added to existing 4 Series Sprayer models.

How it works

The ExactApply system features multiple modes of operation including pulse-width modulation (PWM) and individual nozzle control:

- 15-Hz PWM pulses one solenoid to achieve a consistent droplet size and maintain spray pressure throughout a wider range of speeds and application rates.

- 30-Hz PWM (combined mode) pulses both solenoids in the ExactApply nozzle body at 15 Hz, providing superior coverage. Combined mode allows ExactApply to have a 25 percent increased flow over current competitive systems in the market.

- AutoSelect A/B automatically switches between two nozzles to maintain the desired spray pressure range while spraying conventionally.

- Turn compensation varies the rate across the boom, ensuring the desired application rate. The rate decreases on the inside of the turn to not subject crop to chemical burn, while the rate on the outside of boom increases, ensuring the crop receives the desired application rate.

- Individual nozzle control minimizes overlap by controlling product application through individual nozzles. This reduces chemical cost and ensures the product is placed where it is needed most. In comparison, traditional nozzle control functions in 11 sections, meaning section widths vary from 2.4 to 3.35 m (8 to 11 ft), depending upon boom width.

Take advantage of the R4023 designed for versatility

Built with the same kind of innovative thinking as its popular 4 Series siblings, the R4023 Self-Propelled Sprayer combines versatility, productivity, and affordability in a 2271-L (600-gal.) sprayer.

The option of either a wide or narrow axle configuration enables this sprayer to fit a wide range of row spacing needs. Additionally, the R4023 offers key features that provide for a smooth ride that is necessary for those long days in the field.

Equipped with up to a 27.4-m (90-ft) fold feature, the R4023 allows the operator to fold the boom in quickly for headland turns. With the ability to add precision ag productivity boosting features, the R4023 enables more accurate, efficient, and comfortable spraying applications.

24.4-m and 27.4-m (80-ft and 90-ft) booms can fold in outer wing to spray in tight spaces

Interchangeable inner booms

Interchangeable inner booms

3D boom structure

3D boom structure

The R4023 Sprayer's booms are built with high-strength square tube.

The boom incorporates a strong 3D design. This design gives the boom more strength to resist fore-aft loading generated by starts, stops, and turns, as well as twisting loads caused by folding and unfolding operations.

The boom plumbing and nozzles are set between and up inside the two bottom square tubes of the boom structure. This protects the nozzle bodies from hitting objects that could damage the sprayer or affect the spray pattern.

The R4023 boom comes in an 18.3-m/24.4-m (60-ft/80-ft) or 18.3-m/27.4-m (60-ft/90-ft) configuration. Simply fold in the outer wing and go from spraying at 24.4 m/27.4 m to 18.3 m (80 ft/90 ft to 60 ft). When the outer wing is folded over top, it is supported by cradles to ensure it remains in place and secure while spraying in the 18.3-m (60-ft) configuration in rough fields.

Increased boom sections provide the operator more precise application:

- 24.4-m (80-ft) boom-five sections

- 27.4-m (90-ft) boom-seven sections

The breakaway ends of the boom offer the operator protection against damaging the boom if the boom unexpectedly hits an obstacle. The breakaway section of the boom uses a design that holds the breakaway from breaking backward while operating normally in the field, but when something is contacted, it moves rearward and out of the way to prevent major damage.

Each breakaway section resets using a spring, and then resets back to the spray position.

When the booms are folded in, the transport cradles on the machine support a large portion of the boom that, in turn, spreads out the stress.

While in transport position, the booms are cradled so that visibility is maximized to either side of the sprayer. By folding the booms flat, visibility is increased and overall height of the machine is not affected.

Turbocharged PowerTech™ PSS 4.5L Tier 4 diesel engine delivers 129 kW (173 hp)

4.5L John Deere PowerTech PSS diesel engine

4.5L John Deere PowerTech PSS diesel engine

The R4023 Sprayer provides 129 kW (173 hp) with a 5 percent power bulge to 136 kW (182 hp) and 6071 kg/cu m (538 lb-ft) of peak torque to get through tough field conditions.

John Deere PowerTech PSS (two-valve) 4.5L engine features include:

- Four-cylinder, eight-valve head (two valves per cylinder)

- Cooled exhaust gas recirculation (EGR)

- Exhaust filters

- Selective catalytic reduction (SCR)

- Air-to-air charge air cooler (CAC), aftercooled

- High-pressure common rail (HPCR) fuel injection system

- Series turbocharger

In addition to reducing emissions and lowering engine idle noise, its compact size allows it to fit neatly under the hood for great visibility of the rows passing underneath the operator.

An increase in fuel tank size makes it possible to spray for up to 16 hours without refueling. By equipping the R4023 Sprayer with a 310-L (82-gal.) fuel tank, the operator will have plenty of fuel to spray for a full day.

Handle rough and uneven terrain with ease through soft shock technology

The R4023 offers two factory installed shock solutions to accommodate various field conditions. For optimal comfort in rough or uneven terrain conditions such as no-till or stripped fields, a Soft Shock option is now available.

The Soft Shock takes the place of the adjustable shock dampener used on the 4630 and is offered as a factory-installed option. This fixed shock provides 50 percent less dampening force which allows for a smooth ride up to 32.2-km/h (20-mph) spray speed in uneven field conditions. The Soft Shock may also provide a more responsive feel for operators in turns or when starting/stopping quickly.

NOTE: The standard shock option is unchanged from previous models and is recommended for general use.

Fit variety of cropping row widths with wide and narrow axle options

Wide axle, 234 cm to 307 cm (92 in. to 121 in.)

Wide axle, 234 cm to 307 cm (92 in. to 121 in.)

Narrow axle, 183 cm to 224 cm (72 in. to 88 in.)

Narrow axle, 183 cm to 224 cm (72 in. to 88 in.)

Two axle widths are available to best fit a variety of cropping row widths.

The narrow width axle has a tread width from 183 cm to 224 cm (72 in. to 88 in.) and a clearance of 112 cm (44 in.). The wide axle has a tread width from 234 cm to 307 cm (92 in. to 121 in.) and a clearance of 127 cm (50 in.). Axle range for wide machines varies slightly depending on the option (hydraulic vs. manual tread adjust) that is being used.

NOTE: In order to achieve 229-cm (90-in.) tread spacing, IF320/80R42 tires must be used with AN401678 rims. Please see your local John Deere Dealer for more information.

With these tread spacings, the R4023 Sprayer holds an impressive 46-54 weight split when unfolded, fully loaded. This weight split helps to reduce compaction through the field and keeps the power to the ground.

The wide axle is ideal for the Midwest grain farmer. With the wide axle option, the operator can straddle three rows at 76.2-cm (30-in.), 81.3-cm (32-in.), 86.4-cm (34-in.), 91.4-cm (36-in.), 96.5-cm (38-in.), or 101.6-cm (40-in.) spacing or four rows at 76.2-cm (30-in.) spacing.

The narrow axle is ideal for the cotton or specialty crop farmer. With the narrow axle option, the operator can straddle two rows at 91.4-cm (36-in.), 96.5-cm (38-in.), or 101.6-cm (40-in.) row spacing.

Optimal weight distribution maximizes window to operate in field

Having the optimal weight distribution results in a lighter footprint leaving less compaction and less damage to the field, allowing the operator to get into the field earlier.

The R4023 Sprayer was built with the optimal weight distribution.

R4023 Self-Propelled Sprayer |

Front weight

(kg, lb) |

Rear

weight

(kg, lb) |

Machine weight

(kg, lb) |

Weight

distribution (percent) |

|

Total |

Total |

Total |

Front |

Rear |

| Base machine empty with booms folded, 24.3-m (80-ft) boom |

5,048 (11,105) |

3,227 (7,100) |

8,275(18,205) |

61 |

39 |

| Base machine empty with booms unfolded, 24.3-m (80-ft) boom |

4,220 (9,285) |

4,055 (8,920) |

8,275 (18,205) |

51 |

49 |

| Base machine full water with booms folded, 24.3-m (80-ft) boom |

5,912 (13,006) |

5,036 (11,079) |

10,948 (24,086) |

54 |

46 |

| Base machine full water with booms unfolded, 24.3-m (80-ft) boom |

5,146 (11,320) |

5,802 (12,765) |

10,948 (24,086) |

47 |

53 |

CommandARM™ console and multifunction handle position controls within easy reach for improved operator experience

R4023 operator station

R4023 operator station

When operators first enter the model year 2018 R4023 cab, they will notice that there have been significant changes made. Key sprayer controls are more easily accessible to the operator on the redesigned CommandARM and the multifunction handle has a more ergonomic fit and feel.

The multifunction handle has six reconfigurable buttons, a scroll to select speed range, and allows operators to better manage their headlands with the Headland Management System (HMS©) button.

To finish out the upgrades, the GreenStar© display has been upgraded to a faster, more user-friendly 4600 CommandCenter© display, which allows operators to efficiently capture, manage, and transfer data.

Precision Ag Technology enables you to monitor performance and maximize productivity

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile overview

John Deere Connect Mobile is a solution that utilizes an Apple® iPad® tablet in the cab that provides the operator a better understanding of the sprayer’s performance. Connect Mobile documents and displays several sprayer performance attributes, helping the operator monitor and more easily detect problems that can occur while spraying. Connect Mobile also has a common user interface that makes it easy to use between different pieces of John Deere equipment. Once the job is done, the iPad with the spraying data can be utilized to perform basic crop scouting activities in the field.

Spraying attributes

Monitor key performance indicators in map layers and dashboard tiles such as:

- Actual rate

- Rate deviation

- Pressure

- Ground speed

- Droplet size

- Target rate

- Flow rate

- Tank volume

- Productivity

- Fuel rate

In base equipment

Connect Mobile hardware is factory installed on all model year 2022 and newer 408R, 410R, 412R, 612R, 616R, 400 and 600 Series Sprayers and dry machines as well as model year 2017 to 2021 R4030, R4038, R4044, R4045, and R4060 Sprayers, making it easy to get started with Connect Mobile.

Learn more about Connect Mobile in the Field and Crop Solutions section within the Precision Ag Technology product line and how it can improve the quality of a spraying job.

iPad and Apple are trademarks of Apple Inc.

Gain the advantages of a JDLink™ connected machine

Monitor machines on the go and make adjustments when it matters most

Monitor machines on the go and make adjustments when it matters most

Connectivity provides data that drives better decisions

Connectivity provides data that drives better decisions

Producer needs and their success is John Deere’s focus. As functionality becomes more accepted and even expected, that functionality moves from being optional to being included with the machine. In model year 2019, AutoTrac© guidance and documentation was included on machines equipped with a 4600 CommandCenter© Display. Five years of JDLink is also included with the purchase of all model year 2020 and newer machines equipped with a 4G LTE Modular Telematics Gateway (MTG). The functionality of JDLink on these machines includes everything that was previously included with JDLink Access + Remote Display Access (RDA) and JDLink Connect subscriptions. This added connectivity enables customers to realize the value of a connected machine more easily.

- Easily transfer data and collaborate with trusted advisors to plan your field work quickly. You or your employees can spend more time in the field working rather than sitting on a headland setting up the technology. With a connection between John Deere Operations Center and your machines, changes to field plans occur as needed. Those changes may include changes in varieties, application rates, or machines.

- Better enable data-driven decisions. By using the insights gathered from machines along with the tools in Operations Center (e.g., Field Analyzer, Field Analyzer Beta, and Machine Analyzer) you can understand how your fields are performing and what field plans had an impact. John Deere Operations Center gives you access to more than 100 connected software tools, so you have the ultimate choice of popular industry tools. And, if you don't want to analyze the data yourself, you can share the data with those that help you make decisions to provide the insights you need.

- Report work completed accurately and timely for compliance and billing purposes.

- Increase machine uptime with Connected Support. Your local John Deere dealer can provide remote monitoring services and diagnostics to help keep your machines up and running, reduce your maintenance expenses through early detection of problems, and provide over-the-air software updates for displays, receivers, and controllers.

- Get quick in-field support with RDA. You can monitor your machines from your office computer or a mobile device on the go.

- Remotely manage machines and employees to give you insights into how they are performing. If machines are being underutilized or field operations are not being properly conducted, you can put plans in place to improve productivity.

- Quickly make changes to improve your harvesting operations by remotely viewing and adjusting combine settings.

To use JDLink, the following is required:

- MTG

- JDLink connectivity service

- A John Deere Operations Center account to access machine and agronomic data

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink© telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

Cover more acres more accurately and more consistently with ExactApply™ system

Turn compensation mode

Turn compensation mode

Individual nozzle control mode

Individual nozzle control mode

Fertilizers and crop protection products are too expensive to waste, and seed is too valuable to risk over- or under-treating. To help make sure your solution is getting to the crop at exactly the right rate and droplet size across a wider range of speeds, look to ExactApply nozzle control system.

The heart of the ExactApply system is a six-nozzle turret with multiple modes of operation to help maintain target rate and pressure. From the cab, operators can choose:

- 15-Hz pulse-width modulation (PWM) pulses one solenoid for more consistent pressure and droplet size over a wider range of ground speeds and application rates.

- 30-Hz PWM pulses both solenoids at 15 Hz for more thorough coverage during high-volume applications, like liquid fertilizer.

- AutoSelect A/B mode automatically switches between two nozzles to maintain a constant spray pressure while you’re spraying conventionally.

- Turn compensation mode decreases the spray rate on the inside of a turn while increasing the rate on the outside, ensuring consistent application across the entire width of the boom.

- Individual nozzle control minimizes overlap by controlling spray application at the individual nozzle level, not in 2.4- to 3.35-m (8- to 11-ft) section widths.

By maintaining a target rate and pressure over a wider range of speeds, ExactApply lets you cover up to 20 more acres per hour (based on a 3.2-km/h [2-mph] increase in operating speed) with more consistent spray deposition, saving you input costs and preserving more of your crop’s yield potential.

ExactApply is available as a factory-installed option, as well as through Precision Upgrades and aftermarket attachments. Precision Upgrades for ExactApply are available for 400, 600, and 4 Series Sprayer models. ExactApply aftermarket attachment kits are available for 4 Series Sprayer models.

Take advantage of the R4023, designed for versatility

R4023 Sprayer

R4023 Sprayer

R4023 spraying in the field

R4023 spraying in the field

Built with the same kind of innovative thinking as its popular 4 Series siblings, the R4023 Self-Propelled Sprayer combines versatility, productivity, and affordability in a 2271-L (600-gal.) sprayer.

The option of either a wide or narrow axle configuration enables this sprayer to fit a wide range of row spacing needs. Additionally, the R4023 offers key features that provide for a smooth ride that is necessary for those long days in the field.

Equipped with up to a 27.4-m (90-ft) fold feature, the R4023 allows the operator to fold the boom in quickly for headland turns. With the ability to add precision ag productivity boosting features, the R4023 enables more accurate, efficient, and comfortable spraying applications.

Turbocharged PowerTech™ PSS 4.5L (274.6-cu in.) Tier 4 diesel engine delivers 129 kW (173 hp)

4.5L (274.6-cu in.) John Deere PowerTech PSS diesel engine

4.5L (274.6-cu in.) John Deere PowerTech PSS diesel engine

The R4023 Sprayer provides 129 kW (173 hp) with a 5 percent power bulge to 136 kW (182 hp) and 6071 kg/cu m (538 lb-ft) of peak torque to get through tough field conditions.

John Deere PowerTech PSS (two-valve) 4.5L (274.6-cu in.) engine features include:

- Four-cylinder, eight-valve head (two valves per cylinder)

- Cooled exhaust gas recirculation (EGR)

- Exhaust filters

- Selective catalytic reduction (SCR)

- Air-to-air charge air cooler (CAC), aftercooled

- High-pressure common rail (HPCR) fuel injection system

- Series turbocharger

In addition to reducing emissions and lowering engine idle noise, its compact size allows it to fit neatly under the hood for great visibility of the rows passing underneath the operator.

An increase in fuel tank size makes it possible to spray for up to 16 hours without refueling. By equipping the R4023 Sprayer with a 310-L (82-gal.) fuel tank, the operator will have plenty of fuel to spray for a full day.

Bumps, rolls, and hills: BoomTrac™ Pro 2 system can handle it all

Boom sensor

Boom sensor

For the highest level of spray accuracy with less drift and reduced risk of boom damage, look to the BoomTrac Pro 2 automatic boom-height control system.

Thanks to the addition of an inertia-monitoring sensor that helps correct for chassis roll, BoomTrac Pro 2 offers up to 22 percent greater spray accuracy (composite score over a variety of terrains) compared to the previous BoomTrac Pro system, and a five time increase in the amount of time the boom maintains its target height, which is a real plus in rough or hilly conditions. Along with the improved accuracy and reduced drift, operators will appreciate having one less function to perform and one less thing to worry about.

NOTE: BoomTrac Pro 2 is required on all carbon fiber booms.

CommandARM™ console and multi-function lever position controls within easy reach for improved operator experience

R4023 operator station

R4023 operator station

When operators first enter the R4023 cab, they notice that there have been significant changes made from previous years. Key sprayer controls are more easily accessible to the operator on the redesigned CommandARM console, and the multi-function lever has a more ergonomic fit and feel.

The multi-function lever has six reconfigurable buttons, a scroll to select speed range, and allows operators to better manage their headlands with the HMS© headland management system button.

To finish out the upgrades, the GreenStar© display has been upgraded to a faster, more user-friendly 4600 CommandCenter© Display, which allows operators to efficiently capture, manage, and transfer data.

|

Key Specs

|

| Engine |

Peak rated power

129 kW

173 hp

|

| Solution system - Capacity |

2300 L

600 gal. |

|

Solution system

|

| Rinse tank capacity |

265 L

70 gal. |

|

Key Specs

|

| Boom length options/Material |

18/24.4 or 18/27.4 m

60/80 or 60/90 ft

Boom material: Steel |

|

Drivetrain

|

| Spray speed range |

0 to 32 km/h

0 to 20 mph |

| Transport speed, maximum |

43 km/h

27 mph |

|

Chassis

|

| Suspension |

Air bar/shock suspended |

| Crop clearance with standard tires |

Narrow - 112 cm

44 in.

Wide - 127 cm

50 in. |

|

Engine

|

| Peak rated power |

129 kW

173 hp |

| Emissions |

Final Tier 4 |

| Number of cylinders |

4 |

| Displacement |

4.5 L

276 cu in. |

| Fuel tank capacity |

310 L

82 gal. |

| Diesel exhaust fluid (DEF) tank capacity |

17 L

4.5 gal. |

|

Solution system

|

| Capacity |

2300 L

600 gal. |

| Tank material |

Polyethylene |

| Quick fill size |

5.1 cm

2 in. |

| Automatic section control |

John Deere Section Control (optional) |

| Solution system control |

Manual |

| Fill location |

Side fill |

| Chemical eductor |

Stainless steel |

| Chemical eductor capacity (size) |

20 L

5.5 gal. |

| Flow meter size |

5.1 cm

2 in. |

| Suction strainer |

16 mesh |

| Pressure strainer |

50 mesh |

| Boom strainer |

80 mesh |

|

Boom

|

| Boom length options |

18/24.4 or 18/27.4 m

60/80 or 60/90 ft |

| Automatic boom height |

BoomTrac Pro - 3 sensor (optional) |

| Plumbing material |

Polypropylene |

| Boom Material |

Steel |

| Ground height adjustment |

38 to 193 cm

15 to 76 in. |

| Breakaway width |

1.83 m

6 ft |

| Boom sections |

Five or seven |

| ExactApply™ Nozzle Spacings |

N/A |

|

Drivetrain

|

| Type |

Hydrostatic tandem Saur pumps

Pump size is tandem - 75 cc

4.58 cu in. |

| Drive |

Full-time four-wheel drive (4WD) |

| Shifting |

Electrohydraulic (on the go) |

| Hydraulic reservoir capacity |

61 L

16 gal. |

|

Chassis

|

| Dry compatible |

No |

| Front tires |

IF320/80R42, 380/R80R38, IF380/80R38, or 420/85R34 |

| Rear tires |

IF320/80R42, 380/R80R38, IF380/80R38, or 420/85R34 |

| Hydraulic tread adjust |

Manual standard

Hydraulic optional (wide only) |

| Wheel tread spacing |

Narrow - 183 to 224 cm

72 to 88 in.

Wide - 229 to 305 cm

90 to 120 in. |

| Wheel base |

373 cm

147 in. |

| Turning radius |

4.9 m

16 ft |

| Parking brake |

Hydraulic release |

| Primary brakes |

Hydrostatic |

| Ladder raise/lower |

Hydraulic |

| Total weight with 80-ft boom |

8,240 kg

18,165 lb |

|

Options

|

| Air compressor |

Standard |

| Foam marker capacity |

Direct injection optional |

|

Engine

|

| Rated engine power |

129 kW

173 hp |

|

Boom

|

| Nozzle spacings |

Not applicable |

Accessories and Attachments

Standard Shock Absorber - BKK10300

Soft Shock Absorber (Rough Terrain Application) - BKK10301

12V Pump Kit - SWDEF12VKIT

2.5 gal jug of John Deere Diesel Exhaust Fluid - SWDEF025

20gal Portable Dispensing Unit with lockable, hinged lid - SWDEFPDU20T

275gal tote of John Deere Diesel Exhaust Fluid - SWDEF275

330gal tote of John Deere Diesel Exhaust Fluid - SWDEF330

55gal drum of John Deere Diesel Exhaust Fluid - SWDEF055

60gal Portable Dispensing Unit with lockable, hinged lid - SWDEFPDU60T

110V Pump Kit - SWDEF110VKIT

Steering Toe Counterbalance Valve Kit - BN400489

Fire Extinguisher - TY26852

Fenders for Row-Crop Tires, Wide Tread Spacing (Qty. 4) - BN202582

Fenders for Row Crop Tires, Narrow Tread Spacing (Qty. 4) - BN202583

Shields - Underframe Shields - BKK10284

Auxiliary Work Light Kit (2 Lights) - LVB25720

Floodlamp/Work Lights, LED, (4 Lights) - BSJ10163

Power Strip with Six Outlets - RE68495

Satellite Receiver and Antenna Only (Bosch Specific) - BSJ10122

Instructional Seat - LVB25717

The Field Office is ideal for storage of items such as a laptop computer, cellular phone, papers, writing material, and other uses.

3-Position Nozzle Body Custom Spacing Plumbing Kit

for 80 Ft. Boom ONLY -

1 In. Polypropylene Pipe Wet Plumbing with (65) 3-Position Nozzle Bodies - BN300006

Boom Plumbing Cleanout - BN202517

Cam-lock couplers for quick cleanout

Cam-lock couplers for quick cleanoutDue to popular request, a boom cleanout kit is available as a field-installed bundle. This bundle consists of cam-lock couplers that fit to the end of each solution plumbing pipe.

Quickly remove the cam-lock covers to drain each boom section.

BoomTrac Pro 3-Sensor Automatic Boom Leveling System - BKK10306

The BoomTrac Pro auto-boom height-sensing system is designed to help make operators more productive by providing the following advantages:

BoomTrac Pro increases application accuracy and efficiency by maintaining a more consistent boom height above the crop; drift and skips can be greatly reduced.

Operator fatigue is reduced because the operator has fewer operations to perform. The operator will feel better at the end of the day and pay more attention to the surrounding environment and field conditions.

By reducing opportunities for the boom to contact the ground the likelihood of boom damage decreases, which reduces downtime and repair costs.

Chemical Eductor, (Stainless Steel) - BN300005

Fence Row Nozzle (Left or Right Side) (Qty. 1) - BN300004

Vandal Protection, Door Locks - Custom Key - AL71345