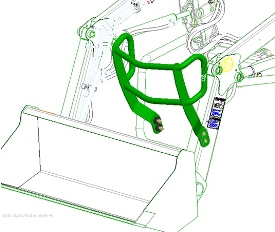

Feature Overview

John Deere 120R

- Compatible with the 1023E, 1025R and 2025R tractors

- Quik-Park stands for easy attachment and removal

- up to 553 lb (251 kg) lift capacity

- Mechanical Self-Leveling (MSL) Loader option with up to 726 lb (330 kg) lift capacity

| Maximum lift height (A) | 1828 mm / 72 in. |

| Clearance at full height - bucket dumped (C) | 1304 mm / 51.3 in. |

| Dump angle, degrees (E) | -40.5 degree (angle) |

| Rollback angle, degrees (G) | 30.08 degree (angle) |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories

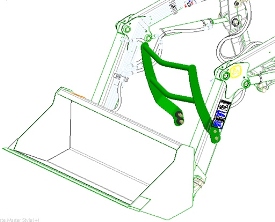

Feature Overview

John Deere 120R

- Compatible with the 1023E, 1025R and 2025R tractors

- Quik-Park stands for easy attachment and removal

- up to 553 lb (251 kg) lift capacity

- Mechanical Self-Leveling (MSL) Loader option with up to 726 lb (330 kg) lift capacity

| Maximum lift height (A) | 1828 mm / 72 in. |

| Clearance at full height - bucket dumped (C) | 1304 mm / 51.3 in. |

| Dump angle, degrees (E) | -40.5 degree (angle) |

| Rollback angle, degrees (G) | 30.08 degree (angle) |

*Inventory shortages may cause extended delivery dates

*This price does not include attachments and accesories