A durable, mechanical front-wheel drive (MFWD) axle increases traction in tough conditions

Heavy-duty MFWD front axle with limited slip

Heavy-duty MFWD front axle with limited slip

MFWD 55-degree turn angle

MFWD 55-degree turn angle

MFWD indicator light

MFWD indicator light

Limited-slip, heavy-duty MFWD front axle will provide operators with increased drawbar pull and improved traction when operating in slippery conditions. This ensures the operator gets the required torque to the ground for applications that demand more from the tractor. The MFWD front axle also reduces wheel slippage with less tractor ballasting for reduced soil compaction, increased fuel economy, and longer tire life.

The MFWD centerline design provides excellent maneuverability around the worksite and more crop clearance so producers aren't driving down their crop or profits. Additional versatility is proven when wheel treads are adjusted with 6 degrees of caster angle and a 55-degree turn angle, which results in a turning radius as short as 3 m (9.9 ft) (brakes applied), allowing plenty of horsepower to turn around in tight places. 10 degrees of axle oscillation follows uneven terrain, allowing for consistent performance and comfortable ride.

Axle oscillation also reduces the stress and maintenance cost on the axle spindles because loads are consistently spread across the entire axle. The centerline design eliminates the need for drive shaft universal joints that require regular maintenance. Anti-wrap shielding on the driveline is standard to prevent crop material and debris from building around the driveline and ensures tractor performance. Three grease points are conveniently located to minimize maintenance time while maximizing front axle performance.

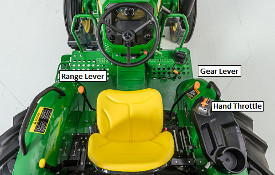

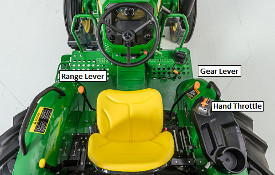

NOTE: The MFWD engagement lever is located on the left-hand side of the operator's seat. For the operator’s convenience, when MFWD is engaged, an indicator light will appear on the dash.

Intuitive controls to aide in simple operation

Adding ease to operation

Enhanced operator controls

Enhanced operator controls

Operator comfort is important regardless of the application. Improving the 5E 3-Cylinder Tractor models, the hand throttle has been relocated to the right-hand console. This is 30.5 cm (12-in.) closer to the operator and within easy reach versus the previous location on the center-hand console. Operators may also notice the additional legroom provided by the repositioned loader controls, providing a more enjoyable experience.

9F/3R SyncShuttle™ transmission - An easy-to-use transmission which saves time and effort

Nine forward and three reverse speeds with in-line synchronized shuttle shifting

The SyncShuttle transmission is designed to match the excellent power and torque characteristics of the John Deere PowerTech© engines. Transmission durability is enhanced with the pressure-lubricated top shaft, allowing an operator to achieve performance from one working season to the next. Additionally, this in-base transmission is configured with fixed draft links, single-speed power take-off (PTO) and mechanical PTO engagement.

The transmission is characterized as full top shaft synchronized (TSS) when forward shifting on-the-go between speeds, and is characterized a synchronized while depressing the clutch.

| 2100 engine rpm |

| |

|

16.9-28 |

| |

Tire |

0.671 RR |

| Gear |

Rear Wheel Speed |

Ground Speed |

| |

rpm |

kmph |

| A1 |

9.1 |

2.3 |

| A2 |

12.4 |

3.1 |

| A3 |

17.0 |

4.3 |

| A Rev |

-13.5 |

-3.4 |

| B1 |

23.1 |

5.8 |

| B2 |

31.4 |

7.9 |

| B3 |

43.2 |

10.9 |

| B Rev |

-34.2 |

-8.6 |

| C1 |

58.9 |

14.9 |

| C2 |

80.3 |

20.3 |

| C3 |

110.3 |

27.9 |

| C Rev |

-87.3 |

-22.1 |

Creeper available for R2 and R4 as field installed kit with following speeds in kmph.

| Creeper 1 |

0.40 |

| Creeper 2 |

0.54 |

| Creeper 3 |

0.75 |

| Creeper Rev |

-0.59 |

Easy and comfortable shifting

Operator-friendly transmission controls with hand throttle

Operator-friendly transmission controls with hand throttle

Synchronized shifting in all forward and reverse gears

Synchronized shifting in all forward and reverse gears

Range selection pattern

Range selection pattern

Nine forward and three reverse (9F/3R) speeds are achieved by using two platform-mounted levers for shift operation. The gear lever at the operator's right hand selects one of three forward gears and one reverse gear, as well as the integrated park position. The range lever at the operator's left hand selects collar-shift A, B, and C ranges.

Operators can easily switch directions without having to completely stop the tractor with synchronized, in-line, shuttle-shift capability between forward and reverse gears on the gear-shift lever in all three ranges (A, B, and C ranges).

A neutral start switch requires the gear-shift lever be in the neutral or park positions to start the engine.

A positive park pawl on the transmission provides positive park and eliminates the need for a hand brake. This also eliminates clutch service costs that occur when the park brake is accidentally left engaged.

12F/12R PowrReverser™ transmission is ideal for demanding applications

Electrohydraulic reverser lever

Electrohydraulic reverser lever

The John Deere-built PowrReverser transmission provides 12 forward and 12 reverse gears for operators requiring additional flexibility for multiple applications. It comes standard with shiftable 540/540 Economy power take-off (PTO) and electronically activated, telescoping draft links. This transmission is ideal for operators using their tractors to perform in versatile applications.

Hydraulic wet forward and reverse clutches maximize durability and will outlast the life of any dry clutch. When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs.

The gear lever selects one of four speeds, all synchronized shifts for on-the-go shifting with the use of the clutch. The range lever selects collar-shift A, B, and C ranges, which are not synchronized.

Maximum productivity is achieved with hydraulic PowerShift between forward and reverse and is ideal for loader and rear-blade applications that require frequent directional switches in tight spaces. Excellent modulation allows the operator to shift the direction lever from neutral to forward or reverse, forward to reverse, reverse to forward, or to neutral from forward or reverse.

Operators can accomplish all these directional changes without sacrificing comfort or having to depress the clutch pedal. The speed of directional changes can be adjusted to the operator's preference or application demands with the field-installed infinitely-variable control kit.

The PowrReverser transmission also allows the operator to steer and shift direction with the left hand, freeing the right hand to operate other tractor controls, such as the loader, rear implements, or hand throttle.

5075E

5075E

Constant-mesh, helical-cut gears provide quieter operation and excellent reliability while the pressure-lubricated top shaft adds to the transmission durability. Fully enclosed, rigid shift linkages for short throw and crisp shifts enable all operators to clearly know in what range and gear they are operating.

Positive park pawl on the transmission provides positive park and eliminates the need for a hand brake.

This also eliminates clutch service costs that occur when the park brake is accidentally left engaged. A neutral start switch requires the directional lever to be in the neutral position to start the engine.

Configurations available

- 5055E-5075E: two-wheel drive (2WD)/four-wheel drive (4WD) in both open operator station (OOS) and cab models

- 9F/3R and 12F/12R transmission offerings

- Loader compatibility: 512 or 520M Loader

NOTE: Loader prep package from the factory will be for the 520M Loader only.

Speed chart

| Gear |

Total ratio |

Speed |

| A1 |

337.841 |

1.62 km/h (1 mph) |

| A2 |

249.499 |

2.19 km/h (1.36 mph) |

| A3 |

184.589 |

2.96 km/h (1.84 mph) |

| A4 |

139.094 |

3.93 km/h (2.44 mph) |

| B1 |

117.21 |

4.66 km/h (2.89 mph) |

| B2 |

86.561 |

6.31 km/h (3.92 mph) |

| B3 |

64.041 |

8.53 km/h (5.3 mph) |

| B4 |

48.257 |

11.32 km/h (7.04 mph) |

| C1 |

40.541 |

13.47 km/h (8.37 mph) |

| C2 |

29.94 |

18.25 km/h (11.34 mph) |

| C3 |

22.151 |

24.66 km/h (15.32 mph) |

| C4 |

16.691 |

32.73 km/h (20.34 mph) |

NOTE: 16.9x30 tire, 0.69-m (2.26-ft) tire radius, 2100 engine rpm.

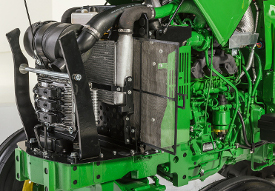

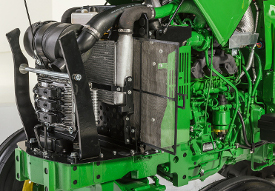

Final Tier 4-compliant PowerTech™ engines provide improved visibility

A smaller, more efficient after-treatment device provides more space under the hood

A smaller, more efficient after-treatment device provides more space under the hood

The 5045E, 5055E, 5065E, and 5075E Utility Tractors meet U.S. Environmental Protection Agency (EPA) Final Tier 4 (FT4) exhaust emissions regulations with a diesel oxidation catalyst (DOC)/diesel particulate filter (DPF) system. Modifying the after-treatment device resulted in better forward and side visibility around the hood. The hood slope of the updated design is comparable to the Tier 2 tractors previously produced. Similar to the system on the 5M, the purpose of the DOC/DPF combination is to reduce toxic gases emitted from the exhaust, as well as to filter particulate matter to prevent it from becoming airborne.

As the tractor continues to operate over time, as is the case with any filter, the DPF will accumulate particulate matter and will need to be cleaned. It is cleaned through a process called regeneration. During a regeneration cycle, exhaust temperatures increase to burn off the excess particulate matter. On a John Deere 5 Series Tractor equipped with a DOC/DPF, the operator does not need to provide any input to trigger the regeneration process.

Exhaust filter cleaning switch

Exhaust filter cleaning switch

On the dash is an exhaust filter cleaning switch. As long as this switch remains in the auto position, the tractor is in full control of the regeneration process and will regenerate on an as-needed basis during operation. The operator just continues to operate the tractor as normal while the regeneration process takes place.

There may be times a tractor is operating in an environment not suitable for a regeneration cycle, such as in a confined area or during service. For this reason, the bottom section of the exhaust filter cleaning switch can be depressed to disable the regeneration. The disable position allows the operator to temporarily inhibit the regeneration cycle. The operator should return the switch to auto mode as soon as possible to avoid continued soot buildup in the exhaust filter, which can lead to a parked regeneration. John Deere does not recommend disabling the automatic exhaust filter cleaning unless it is absolutely necessary.

The simplicity and intuitiveness of the exhaust filter cleaning switch maximizes uptime by minimizing the operator’s input into the regeneration process. This increases the overall productivity of the tractor by reducing the chances of a parked regeneration. The operator-friendly interface allows the operator to easily complete the task at hand, even during the regeneration process.

Save fuel, reduce noise, and increase engine life in power take-off (PTO) applications with the 540/540 economy PTO

Shiftable 540/540 economy PTO (5E) for cab tractors

Shiftable 540/540 economy PTO (5E) for cab tractors

Shiftable 540/540 economy PTO (5E) for open operator station (OOS) tractors

Shiftable 540/540 economy PTO (5E) for open operator station (OOS) tractors

The 540 economy PTO option comes in base equipment with the 12F/12R PowrReverser© transmission.

The 540/540 economy PTO allows operators to select the engine rpm for reduced fuel consumption, reduced noise levels, reduced vibration, and less wear and tear on the engine, while at the same time keeping the proper 540 rpm at the PTO.

The economy PTO provides 540 rpm to the PTO at 1600 engine rpm. The 540 economy mode is ideal for any PTO application, from running a mower-conditioner to a baler or a cutter, where full engine horsepower is not required.

Operating at lower engine rpm decreases fuel costs up to 30 percent and provides additional productivity by improving the operating experience through enhanced operator comfort from reduced noise and vibration.

A lever allows the operator to simply change between 540 and 540E when conditions merit the opportunity to save fuel without affecting performance.

For heavy-duty operations requiring maximum PTO power, the PTO shift lever is placed in the 540 position, the PTO is engaged, and the engine is run at a rated speed of 2100 rpm. This selection gives 540 rpm to the PTO shaft and delivers the fully advertised horsepower at rated engine speed.

When the cab tractor is in economy PTO mode, the engine is electronically limited to 1600 rpm, preventing accidental over speeding of PTO implements and protecting against binding the PTO shaft.

This interlock also prevents accidental shifting of the PTO selector lever at engine speeds above 1600 rpm, which would lead to downtime for fixing implements or drivetrain components.

Excellent maneuverability, visibility, and comfort in one package with heavy-duty, two-wheel drive (2WD) front axle and cab

2WD front axle and cab on 41- to 55.9-kW (55- to 75-hp) 5E Tractors

2WD front axle and cab on 41- to 55.9-kW (55- to 75-hp) 5E Tractors

Made of heavy-duty steel for added reliability, the 2WD front axle is adjustable in 50.8-mm (2-in.) increments to adapt to a wide variety of applications.

- The front axle provides 10 degrees of axle oscillation, allowing the axle to follow uneven terrain for a consistent performance, comfortable ride, and reduced stress and maintenance costs on axle spindles.

- A 55-degree turn angle provides excellent maneuverability for high-torque tasks in tight spaces.

- The steering cylinder is bolted directly to the rear of the front axle, so the axle housing protects the steering cylinder from potential punctures created by rough terrain, rocky soil conditions, or thick crop material.

Broadening the 5E 3-Cylinder Tractor product lineup to offer a 2WD front axle in a cab configuration provides you with the well-known benefits of the 5E 3-Cylinder Tractors in conjunction with the ability to stay out of the elements and have the tighter turning radius that 2WD front axles provide.

2WD front axle

2WD front axle

Backup Alarm Kit - LVB25817

For operators who require an alarm in reverse speeds to satisfy safety regulations and governmental bid requirements, this alarm is rear mounted and designed to provide optimum clearance from the 3-point hitch.

Backup Alarm Kit - LVB25728

For those who require an alarm in reverse speeds to satisfy safety regulations and governmental bid requirements, this alarm is rear mounted and designed to provide optimum clearance from the 3-point hitch.

Beacon Light Kit - BLV10120

The beacon light kit is for the operator who is required to meet certain requirements for government and commercial applications. The beacon light is not compatible with open operator station (OOS) tractors.

The kit consists of a rotating, high-intensity light that rests inside an amber-colored safety lens. A cab interior roof-mounted rocker switch controls turning on and off the light.

Rear Mirror Mechanical - AL80126

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Rear Mirror Mechanical - AL80127

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Engine Coolant Heater Kit (3 Cyl.) - LV150155

A screw-in type 120-V element heats coolant to warm vital engine parts in cold weather. This ensures fast starts and better lubrication at startup, reducing engine wear. It also provides additional starting capabilities for operators requiring cold-weather operations.

A battery with a minimum of 925 CCA is required.

Rear Fender Extension Kit - LVB25714

Rear fender extension on 5020 Series Tractor

Rear fender extension on 5020 Series TractorProtects the operator from debris.

Rear Fender Extension Kit without Work Lights - BSJ10044

Front Weight Support, 187 Lbs - R262449

Left Hand Telescopic Draft Link - SJ11072

Quik-Coupler, Economy, Category 2 - TY16042

Quick-coupler

Quick-couplerThe second-generation iMatch™ quick-hitch allows a no-hassle attachment option for many integral implements such as box blades, rear blades, rotary tillers, and rotary cutters. The hitch is constructed of tubular and box-welded steel, and the bushings and hooks are heat-treated to prevent cracking for long wear life. Hardened, zinc-plated steel alloy pins take the shock of heavy loads and withstand exposure to the elements. Hitch locking handles rotate 100 degrees to open the locking lugs for easy implement release. The top link is adjustable for compatibility and versatility.

This attachment is only available through Parts.

Mid-Mount Dual SCV with Joystick Control - BLV10347

Mid-Mount Dual SCV with Joystick Control - BSJ10083

Second Rear SCV with Detented Float and Lever Control - BSJ10190

Auxiliary Rear Work Light Kit (1 Light) - LVB25547

Rear work light

Rear work lightA 37.5-W halogen floodlight is adjustable and illuminates areas to the rear of the tractor.

The bulb can be easily replaced as needed.

Mid Selective Control Valves

Mid-Mount Dual SCV with 3rd Function Joystick Assembly - BSJ10346

Mid-Mount Dual SCV with Joystick Control - BSJ10262

Backhoe Mounting Kit - BLV10921

Single Horn Kit - LVB26096

Rear Axle 1.2 In. Extension (30 mm) - L154683

Axle extensions are required to achieve wider tread settings.

Cab Instructional Seat - BLV10419

Canopy - Deluxe - LVB25785

Standard canopy

Standard canopy Deluxe canopy

Deluxe canopyThe canopy attaches to the open operator station rollover protective structure (ROPS).

The 1613.2-mm (63.5-in.) long, 1322.7-mm (52-in.) wide ABS canopy can offer protection to the operator from inclement weather and direct overhead sunlight.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

NOTE: Deluxe canopy (LVB25785) includes additional headliner and marker lights for select open station models and also requires LVB25332.

Rear View Mirror Mounting Kit OOS - RE244177

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

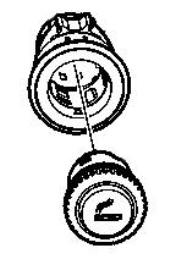

Cigarette Lighter - AR60937

Ashtray

Ashtray Cigarette lighter

Cigarette lighter

Lockable Fuel Tank - AL113087

5025 Series Tractor with lockable fuel cap

5025 Series Tractor with lockable fuel capFor operators concerned about the security of their fuel supply, a lockable fuel cap is available for all 5M platforms and isolated open operator station and cab platforms on the 5025 Series Tractors.

Left-Hand Telescopic Draft Link - SJ11072

Draft Link Conversion Bushing, Cat. II to Cat. I - R66432

Implement hitch pins and bushings adapt Category 1 implements to fit a Category 2 3-point hitch.

Rear Axle 4.4 In. Extension (111 mm) - L154684

Axle extensions are required to achieve wider axle tread settings.

Rear Axle 1.6 In. Extension (40 mm) - L154682

Axle extensions are required to achieve wider axle tread settings.

Single Horn Kit - LVB25926

The electric horn serves as a warning or signal device.

Right-hand door - BLV10350

Front Utility Box Bracket - BRE10153

With loads of capacity, two removable shelves, and an innovative front door and lid design, this new tractor utility box breaks new ground for convenience, versatility, and rugged design. Grease guns, tow chains, hitch pins, and many other essential items can be stored safely and can be easily accessed, putting an end to cluttered cabs.

Front utility box

Front utility box Front utility box and bracket

Front utility box and bracketBuilt from welded, heavy-gauge sheet steel, this new box offers long-term durability not seen with other toolboxes. A heavy-duty gas strut on the lid and locking pins make opening and locking simple and easy.

Specifications:

- Made in the USA

- 23 in. x 8 in. x 12 in.

- Two removable shelves

- Heavy-duty construction

- Fold down front door for easy access

- Mount with existing R127764 tractor weights using BRE10153 bracket

- Mount on 9X30 Series Wheel Tractors (front left side) using BRE10291 bracket

Front Utility Box - BRE10151

With loads of capacity, two removable shelves, and an innovative front door and lid design, this new tractor utility box breaks new ground for convenience, versatility, and rugged design. Grease guns, tow chains, hitch pins, and many other essential items can be stored safely and can be easily accessed, putting an end to cluttered cabs.

Front utility box

Front utility box Front utility box and bracket

Front utility box and bracketBuilt from welded, heavy-gauge sheet steel, this new box offers long-term durability not seen with other toolboxes. A heavy-duty gas strut on the lid and locking pins make opening and locking simple and easy.

Specifications:

- Made in the USA

- 23 in. x 8 in. x 12 in.

- Two removable shelves

- Heavy-duty construction

- Fold down front door for easy access

- Mount with existing R127764 tractor weights using BRE10153 bracket

- Mount on 9X30 Series Wheel Tractors (front left side) using BRE10291 bracket

Creeper Conversion Kit - BSJ10371

Wiper and washer, rear - BLV10173

Wiper kit on 5025 Series Cab Tractor

Wiper kit on 5025 Series Cab TractorThe rear wiper provides better rear visibility during inclement weather. The kit also features a wiper nozzle that disperses fluid to clean the window.

Cell phone mount kit - BRE10015

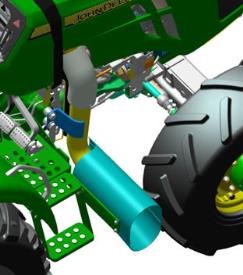

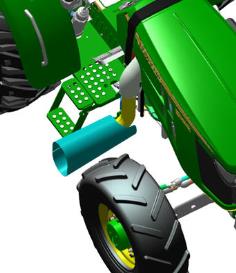

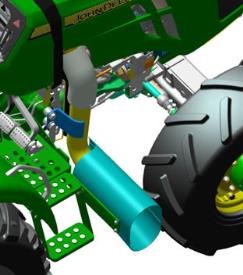

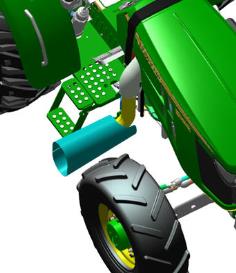

Horizontal Side Exhaust - BSJ10077

Side exhaust for 3-cylinder 5E Tractors

Side exhaust for 3-cylinder 5E Tractors Side exhaust for 3-cylinder 5E Tractors

Side exhaust for 3-cylinder 5E TractorsThe dealer-installed horizontal exhaust kit provides accessibility to producers working in low-clearance applications. Previously seen on older 5E Tractors, this design is compatible with Final Tier 4 emissions on all cab and open-station 5045E, 5055E, 5065E, and 5075E Tractors.

Right Hand Telescopic Draft Link - SJ11073

Drawbar Clevis Kit (Hammer Strap) - Straight Drawbar - RE39829

Straight drawbar clevis kit

Straight drawbar clevis kitThe straight drawbar clevis kit allows quick, no-hassle, safe hookups to many popular drawn implements.

Drawbar Clevis Kit (Hammer Strap) - Offset Drawbar - RE39830

Straight drawbar clevis kit

Straight drawbar clevis kitThe offset drawbar clevis kit allows quick, no-hassle, safe hookups to many popular drawn implements.

Drawbar - Offset - R133359

Offset drawbar

Offset drawbarOffset drawbars can be used with large- or small-diameter tires to raise or lower the drawbar height.

Center Link Conversion Bushing, Cat. II to Cat. I - T12553

Implement hitch pins and bushings adapt Category 1 implements to fit a Category 2 3-point hitch.

Ashtray

Ashtray Cigarette lighter

Cigarette lighter

Wiper/Washer, Rear - BLV10173

Standard Canopy for ROPS - LVB25334

Standard canopy

Standard canopy Deluxe canopy

Deluxe canopyThe canopy attaches to the open operator station rollover protective structure (ROPS).

The 1613.2-mm (63.5-in.) long, 1322.7-mm (52-in.) wide ABS canopy can offer protection to the operator from inclement weather and direct overhead sunlight.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

NOTE: Deluxe canopy (LVB25785) includes additional headliner and marker lights for select open station models and also requires LVB25332.

Right Hand Door - BLV10350

Rear View Mirror Mounting Kit - RE244177

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Mirror, Telescopic, RH, Manually Adjustable - AL80127

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Mirror, Telescopic, LH, Manually Adjustable - AL80126

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Canopy Mounting Bracket and Hardware Kit - LVB25332

Standard canopy

Standard canopy Deluxe canopy

Deluxe canopyThe canopy attaches to the open operator station rollover protective structure (ROPS).

The 1613.2-mm (63.5-in.) long, 1322.7-mm (52-in.) wide ABS canopy can offer protection to the operator from inclement weather and direct overhead sunlight.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

NOTE: Deluxe canopy (LVB25785) includes additional headliner and marker lights for select open station models and also requires LVB25332.

Self - Leveling Cup Holder - BRE10152

A favorite worldwide, the RAM self-leveling cup holder is now available as a kit - designed specifically for Deere equipment. It is easily installed to keep your favorite beverage upright even in the roughest terrain. The perfect accessory for any cab that has 10-mm mounting bosses.

Self-leveling cup holder John Deere branded beverage insulator included

Self-leveling cup holder John Deere branded beverage insulator includedThe new cup holder features a unique self-leveling design. This pivoting design allows easy adjustment for the holder while offsetting motion of the vehicle when moving.

Features and applications:

- Self-leveling action reduces spills

- Durable design for rough environments

- Easy adjustable mounting for ideal placement

- Includes John Deere branded beverage insulator

- Compatible with most monitor brackets and all 10-mm threaded bosses

Radio - AM/FM, Bosch (Premium) - AT439279

Rear Fender Extension Kit without Work Lights - BSJ10303

Rear fender extension - LVB25714

Rear fender extension on 5020 Series Tractor

Rear fender extension on 5020 Series TractorProtects the operator from debris.

Rear Selective Control Valves

Second Rear SCV - BSJ10002

Quik-Coupler, Economy, Category 2 - TY27545

Quick-coupler

Quick-couplerThe second-generation iMatch™ quick-hitch allows a no-hassle attachment option for many integral implements such as box blades, rear blades, rotary tillers, and rotary cutters. The hitch is constructed of tubular and box-welded steel, and the bushings and hooks are heat-treated to prevent cracking for long wear life. Hardened, zinc-plated steel alloy pins take the shock of heavy loads and withstand exposure to the elements. Hitch locking handles rotate 100 degrees to open the locking lugs for easy implement release. The top link is adjustable for compatibility and versatility.

This attachment is only available through Parts.

iMatch Quick-Hitch Category 1 with adjustable top hook - LVB25976

iMatch hitch

iMatch hitchThe iMatch quick-hitch meets ASAE standard S278.6 for Category 1 agricultural quick-coupler standards. Uniform hitch points reduce the amount of effort to attach 3-point hitch implements in minimal time.

PowrReverser Modulation Control Kit - LVB25727

Modulation knob

Modulation knobChange the transition speed of the PowrReverser transmission with a simple dial located near the steering column. This knob is used to adjust modulation sensitivity.

Adjust the aggressiveness of the forward to reverse transition, for either a quick fast transition or a smoother, slower transition.

Creeper Conversion Kit - BSJ10370

Front suitcase weight

Front suitcase weightOne suitcase weight of 43 kg (95 lb).